How Gas Swimming Pool Heaters Work

Gas-fired pool heaters remain the most popular system for heating swimming pools. Today you can find new gas-fired heater models with much higher efficiencies than older models. Still, depending on your climate and pool use, they may not be the most energy-efficient option when compared to heat pump and solar pool heaters.

Gas pool heaters use either natural gas or propane. As the pump circulates the pool's water, the water drawn from the pool passes through a filter and then to the heater. The gas burns in the heater's combustion chamber, generating heat that transfers to the water that's returned to the pool.

They're most efficient when heating pools for short periods of time, and they're ideal for quickly heating pools. Therefore, gas pool heaters can be a good choice for pools that aren't used on a regular basis. Unlike heat pump and solar pool heaters, gas pool heaters can maintain any desired temperature regardless of the weather or climate.

Selecting a Gas Pool Heater

When selecting a gas swimming pool heater, you need to consider the following:

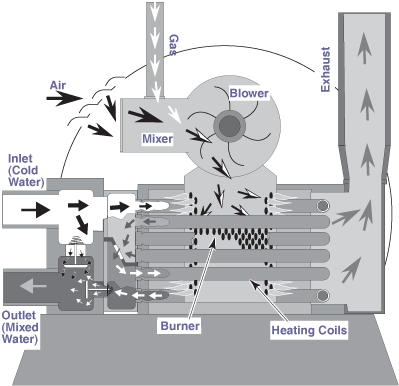

Sample of how a gas heater works.

Precisely matched orifice plates meter the air and gas into the mixer. The blower draws the air and gas through the mixer and forces it into the burner’s flame holder. A sealed heat exchanger surrounds the flame holder, discharging exhaust gases out the flue. Two inch PVC water piping connects directly to the manifold/header on the heat exchanger using 2" PVC slip unions provided with the heater. The outer manifold remains cool; no heat sinks are required. A thermal regulator and an internal bypass regulate the water flow through the heat exchanger to maintain the correct outlet temperature. The heater operator control panel board assembly is located on top of the heater.

Sequence of Operation

An electronic temperature sensing thermistor in the manifold adapter inlet controls the heater operation. When the inlet water temperature drops below the temperature set on the operating control, the burner controller supplies power to the combustion air blower through a series of safety interlocks.

The interlocks consist of:

- the pressure switch (PS), which senses that the pump is running,

- the high limit switch (HLS), which opens if the heat exchanger outlet temperature goes above 135° F (57° C), and

- the air flow switch (AFS), which senses the pressure drop across the air metering orifice,

- the automatic gas shut-off (AGS) switch, which opens if the heat exchanger outlet temperature goes above 140° F (60° C).

- the stack flue sensor (SFS), which shuts down the heater if the flue gas temperature reaches 500° F (260° C).

The air flow switch (AFS) senses the pressure drop across the air metering orifice. As soon as there is sufficient air flow, the AFS closes, closing the circuit to the hot surface igniter (HSI), which ignites the fuel mixture. On a call for heat, the blower and HSI are energized. In about 20 seconds, the gas valve opens and ignition occurs. The HSI then switches to a sensing mode and monitors the flame.

|